Lubrizol unveils LED reactor technology for CPVC manufacturing

PFAS debate sparks national security concerns

Polyplastics develops new long glass fiber PP grades with PCR content

Nova Chemicals adds 2 new grades to its recycled PE portfolio

Xenia launches impact modified PA11 and PA12 grades

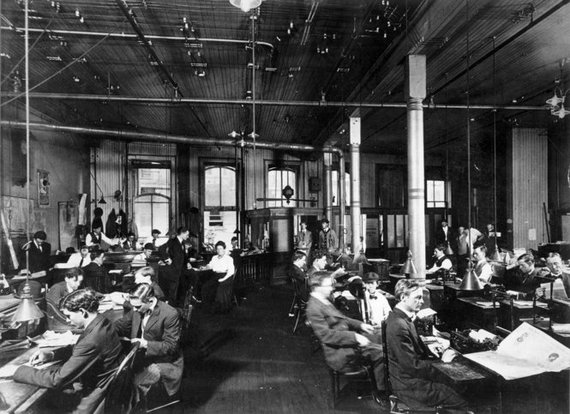

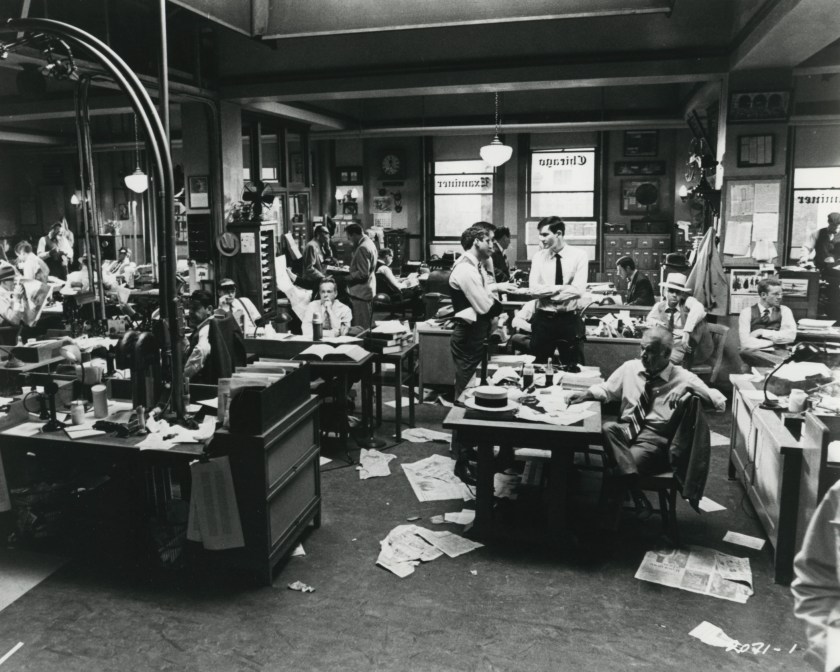

This Week in History

March 5, 1963: The Hula Hoop, made from Phillips Petroleum polyethylene, was patented.